-

umurongo wibyuma byamazi

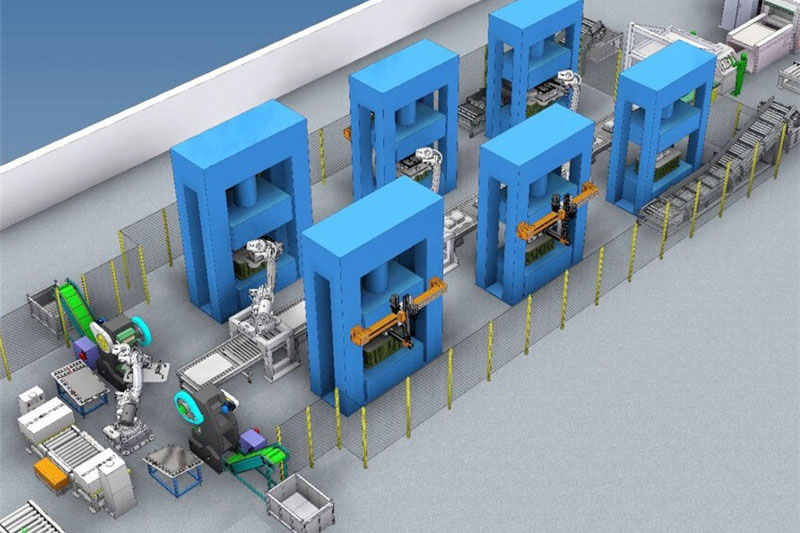

Umurongo wibyuma byamazi adafite umwanda numurongo wogukora wikora urimo inzira nka coil coil idashaka, gukata, no gushiraho kashe kugirango ibe yarohamye. Uyu murongo utanga umusaruro ukoresha robot kugirango usimbuze imirimo yintoki, ituma kurangiza byikora byikora.

Umurongo wibyuma wamazi wibyuma bigizwe nibice bibiri byingenzi: ishami rishinzwe gutanga ibikoresho hamwe na kashe ya kashe. Ibi bice byombi bihujwe nigice cyo kohereza ibikoresho, byorohereza gutwara ibikoresho hagati yabo. Igice cyo gutanga ibikoresho kirimo ibikoresho nka coil uninders, laminator ya firime, ibishishwa, imashini, hamwe na stackers. Igice cyo kohereza ibikoresho kigizwe no kohereza amakarita, imirongo yibikoresho, hamwe nububiko bwa pallet bwubusa. Igice cyo gushiraho kashe kigizwe nuburyo bune: gukata inguni, kurambura kwambere, kurambura kabiri, kurambura impande, bikubiyemo gukoresha imashini zikoresha hydraulic no gukoresha robot.

Ubushobozi bwo gukora uyu murongo ni ibice 2 kumunota, hamwe nibisohoka buri mwaka hafi 230.000.

-

SMC / BMC / GMT / PCM Igizwe na Molding Hydraulic Press

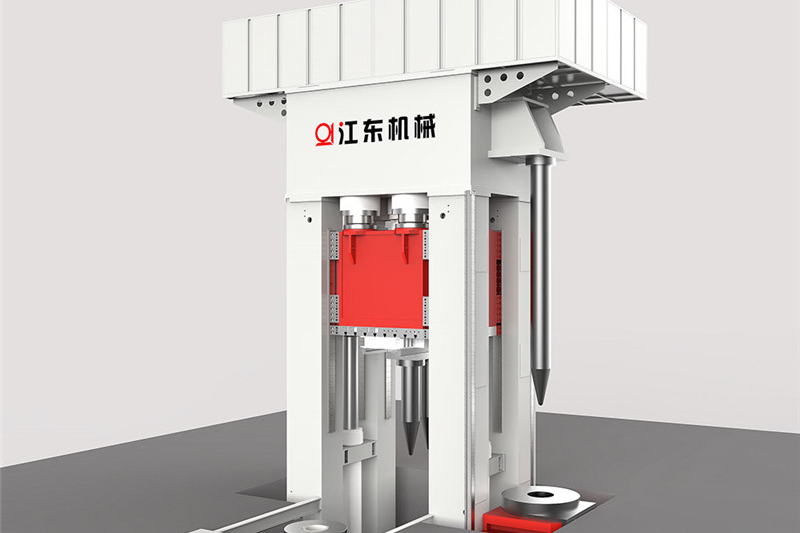

Kugirango ugenzure neza mugihe cyo kubumba, imashini ya hydraulic ifite ibikoresho bigezweho bya sisitemu yo kugenzura hydraulic. Sisitemu yongerera imyanya kugenzura, kugenzura umuvuduko, kugenzura micro gufungura umuvuduko, hamwe nibipimo byerekana neza. Igenzura ryumuvuduko urashobora kugera kuri ± 0.1MPa. Ibipimo nkibice byerekana umwanya, umuvuduko wo hasi, mbere yo gukanda umuvuduko, umuvuduko wo gufungura mikoro, umuvuduko wo kugaruka, hamwe numurongo mwinshi urashobora gushyirwaho no guhindurwa murwego runaka kuri ecran yo gukoraho. Sisitemu yo kugenzura ni ukuzigama ingufu, hamwe n urusaku ruke ningaruka nkeya ya hydraulic, itanga umutekano muke.

Kugira ngo ukemure ibibazo bya tekiniki nkumutwaro utaringanijwe uterwa nuduce duto twa asimmetrike hamwe no gutandukana kwubunini mubicuruzwa binini binini binini, cyangwa kugirango byuzuze ibisabwa nkibishushanyo mbonera hamwe no kumanura hamwe, imashini ya hydraulic irashobora kuba ifite ibikoresho byihuse ako kanya impande enye zingana. Iki gikoresho gikoresha ibyuma bisohora ibyuma bisimburana hamwe na serivise nyinshi zo gusubiza servo valve kugirango igenzure ibikorwa byo gukosora ibikorwa bya silindari enye. Igera kuri ntarengwa enye zinguni zingana zingana na 0.05mm kumeza yose.

-

LFT-D ndende ya fibre yongerewe imbaraga zo guhunika ubushyuhe bwa tropoplastique

LFT-D ndende ya fibre yongerewe imbaraga ya comproplastique compression itondekanya umurongo utanga umusaruro ni igisubizo cyuzuye cyo gukora neza ibikoresho byo murwego rwohejuru. Uyu murongo wo kubyaza umusaruro ugizwe na sisitemu yo kuyobora ibirahuri bya fibre fibre, kuvanga ibirahuri bya fibre fibre plastike ivanga extruder, icyuma gishyushya ibyuma, sisitemu yo gukoresha ibikoresho bya robo, imashini yihuta ya hydraulic, hamwe nigice gishinzwe kugenzura.

Igikorwa cyo kubyaza umusaruro gitangirana na fibre fibre ikomeza kugaburira muri extruder, aho yaciwe ikajyanwa muburyo bwa pellet. Pellet zirashyuha hanyuma zigahinduka muburyo bwifuzwa ukoresheje sisitemu yo gukoresha ibikoresho bya robo hamwe na progaramu ya hydraulic yihuta. Hamwe nubushobozi bwo gutanga umusaruro buri mwaka 300.000 kugeza 400.000, uyu murongo wumusaruro utanga umusaruro mwinshi.

-

Ibikoresho bya Carbone Fibre Yumuvuduko mwinshi Resin Transfer Molding (HP-RTM) ibikoresho

Ibikoresho bya Carbone Fibre Yumuvuduko mwinshi wa resin Transfer Molding (HP-RTM) nigisubizo cyambere cyatejwe imbere murugo kugirango habeho umusaruro mwiza wa karuboni nziza. Uyu murongo wuzuye wibikorwa bigizwe na sisitemu yo guhitamo kubushake, imashini yihariye ya HP-RTM, sisitemu yo gutera inshinge HP-RTM yihuta, imashini za robo, ikigo gishinzwe kugenzura ibicuruzwa, hamwe n’ikigo gikora imashini. Sisitemu yo gutera inshinge HP-RTM igizwe na sisitemu yo gupima, sisitemu ya vacuum, sisitemu yo kugenzura ubushyuhe, hamwe na sisitemu yo gutwara no kubika ibikoresho. Ikoresha uburyo bwumuvuduko mwinshi, uburyo bwo gutera inshinge hamwe nibikoresho bitatu. Imashini yihariye ifite sisitemu yo kuringaniza impande enye, itanga uburinganire butangaje bwa 0.05mm. Iragaragaza kandi ubushobozi bwo gufungura mikoro, ituma umusaruro wihuta wiminota 3-5. Ibi bikoresho bifasha ibyiciro kubyara umusaruro hamwe no gutunganya ibintu byoroshye bya fibre fibre.

-

Gukuramo ibyuma / bishyushye bipfa guhimba hydraulic

Metal extrusion / hot die forging hydraulic press nubuhanga bugezweho bwo gukora ibikoresho byujuje ubuziranenge, bukora neza, kandi buke buke bwo gutunganya ibikoresho byicyuma hamwe na chip ntoya. Yabonye akamaro kanini mu nganda zinyuranye zikora nk'imodoka, imashini, inganda zoroheje, icyogajuru, ingabo, n'ibikoresho by'amashanyarazi.

Metal extrusion / hot die forging hydraulic press yagenewe cyane cyane gukonjesha ubukonje, gususurutsa ubushyuhe, gushyuha, hamwe no gupfa bishyushye bikora, ndetse no kurangiza neza ibyuma.

-

titanium alloy superplastic ikora hydraulic imashini

Imashini ya superplastic ikora Hydraulic imashini ni imashini yihariye yagenewe gukora hafi ya net igizwe nibice bigoye bikozwe mubikoresho bigoye-kubumba hamwe nubushyuhe buke bwo guhinduranya no kurwanya ihindagurika ryinshi. Irasanga ikoreshwa cyane mu nganda nk'ikirere, indege, igisirikare, ingabo, na gari ya moshi yihuta.

Iyi mashini ya hydraulic ikoresha ubudahangarwa bwibikoresho, nka titanium, amavuta ya aluminiyumu, amavuta ya magnesium, hamwe nubushyuhe bwo hejuru cyane, muguhindura ingano yingano yibikoresho fatizo bikaboneka muburyo budasanzwe. Mugukoresha imbaraga zidasanzwe kandi zigenzurwa n'umuvuduko, itangazamakuru rigera kumiterere yibintu. Iyi nzira yo gukora impinduramatwara ituma umusaruro wibigize ukoresheje imitwaro mito ugereranije nubuhanga busanzwe bwo gukora.

-

Gukora hydraulic kubuntu

Imashini yubusa ya Hydraulic Press ni imashini yihariye yagenewe ibikorwa binini byubusa. Ifasha kurangiza inzira zitandukanye zo guhimba nko kurambura, kurakara, gukubita, kwagura, gushushanya umurongo, kugoreka, kunama, guhinduranya, no gutema kugirango habeho ibiti, inkoni, amasahani, disiki, impeta, nibice bigizwe nuruziga na kare. Bifite ibikoresho byunganira byuzuzanya nko guhimba imashini, sisitemu yo gutunganya ibikoresho, ameza y'ibikoresho bizunguruka, anvils, hamwe nuburyo bwo guterura, itangazamakuru rihuza hamwe nibi bice kugirango birangize inzira yo guhimba. Irasanga ibikorwa byinshi mu nganda nko mu kirere no mu ndege, kubaka ubwato, kubyara amashanyarazi, ingufu za kirimbuzi, metallurgie, na peteroli.

-

Umucyo Alloy Liquid Gupfa Kwibeshya / semisolid ikora Umurongo Wumusaruro

Umucyo wa Alloy Liquid Die Forging Production Line ni tekinoroji igezweho ihuza ibyiza byo gutara no guhimba kugirango igere kumurongo-shusho. Uyu murongo wo guhanga udushya utanga inyungu nyinshi, zirimo inzira ngufi, kubungabunga ibidukikije, gukoresha ingufu nke, imiterere yibice bimwe, hamwe nubukorikori bukomeye. Igizwe n'amazi menshi ya CNC apfa guhimba imashini ya hydraulic, sisitemu yo kwisuka ya aluminiyumu, robot, hamwe na sisitemu ihuriweho na bisi. Umurongo wo kubyaza umusaruro urangwa na CNC igenzura, ibintu byubwenge, kandi byoroshye.

-

Umwuka wa gaz Cylinder / Amasasu Amazu ashushanya umurongo

Umurongo wa Vertical Gas Cylinder / Bullet Amazu yo gushushanya Igishushanyo mbonera cyagenewe cyane cyane kubyaza umusaruro ibice bikozwe mu gikombe (kimeze nka barriel) bifite epfo na ruguru, nkibikoresho bitandukanye, silindiri ya gaze, hamwe n’amasasu. Uyu murongo wo kubyara ushoboza inzira eshatu zingenzi: kubabaza, gukubita, no gushushanya. Harimo ibikoresho nkimashini igaburira, itanura rishyushya hagati yumuriro, umukandara wa convoyeur, kugaburira robot / ukuboko kwa mashini, kubabaza no gukubita imashini ya hydraulic, kumeza ya sitasiyo ebyiri, kwimura robot / imashini, gushushanya imashini ya hydraulic, hamwe na sisitemu yo kohereza ibikoresho.

-

Gazi Cylinder Itambitse Gushushanya Umurongo Wumusaruro

Gazi ya silinderi itambitse gushushanya umurongo wateguwe kugirango urambure uburyo bwo kurambura amashanyarazi maremare. Ifashisha tekinike yo gutambuka itambitse, igizwe numurongo wumutwe, robot yipakurura ibikoresho, imashini ndende itambitse, uburyo bwo gusubira inyuma, hamwe numurongo wumurizo. Uyu murongo wo gutanga umusaruro utanga inyungu nyinshi nkibikorwa byoroshye, gukora umuvuduko mwinshi, kurambura birebire, hamwe nurwego rwo hejuru rwo kwikora.

-

Gantry Igorora Hydraulic Kanda kumasahani

Imashini yacu ya gantry igorora hydraulic yakozwe muburyo bwihariye bwo kugorora no gukora ibyapa byibyuma mu nganda nko mu kirere, kubaka ubwato, na metallurgie. Ibikoresho bigizwe na silinderi yimukanwa, ikarita ya gantry igendanwa, hamwe nakazi gakwiye. Hamwe nubushobozi bwo gukora horizontal itambitse kumutwe wa silinderi no kumurongo wa gantry ukurikije uburebure bwakazi, gantry yacu igorora imashini ya hydraulic itanga ikosora neza kandi neza neza idafite isahani ihumye. Silinderi nyamukuru yimashini ifite ibikoresho bya micro-bigenda kumanuka, bituma ibyapa bigororoka neza. Ikigeretse kuri ibyo, imbonerahamwe ikora yateguwe hamwe na silinderi nyinshi yo guterura ahantu heza h'isahani, yorohereza kwinjiza ibibanza byo gukosora ahantu runaka kandi ikanafasha mukuzamura amasahani.kuzamura isahani.

-

Automatic Gantry Straightening Hydraulic Press for Bar Stock

Imashini yacu ya gantry igorora hydraulic imashini ni umurongo wuzuye wo gukora wagenewe kugorora neza no gukosora ububiko bwibyuma. Igizwe na hydraulic igendanwa igendanwa, sisitemu yo kugenzura ibintu (harimo kugaragariza igihangano cyakazi, kugaragariza impande zose, kugaragariza intera intera, no kugorora ibyimuwe), sisitemu yo kugenzura hydraulic, hamwe na sisitemu yo kugenzura amashanyarazi. Imashini itandukanye ya hydraulic irashobora gukora uburyo bwo kugorora ububiko bwibyuma, byemeza neza kandi neza.